Plastics are synthetically produced non-metallic compounds. You can mold it into various forms and for commercial use, it is hardened. Everywhere you can find plastic molding products from mold supplier. The keyboard and the mouse that are used are also made through plastic molding. Using this method even the plastic parts of the chair are also created.

In plastic molding, the basic thing is putting molten liquid plastic

into a readymade mold shape, for example, the bottle mold for the bottle. It is

then allowed to cool and to reveal the plastic bottle the mold is then removed.

This process of injection mold making can also

custom-mold a wide variety of plastic products that includes: barriers, garden

pots, cabinets, barricades and traffic signage, office trays and boxes, and

displays for product and marketing promotions.

the various processes must be known to you need to know if you are want

to go into the plastic molding business. From a plastic molding process, you

can select one that fits your resources, budget, and expertise. Below are the

listed basic definitions of various methods of plastic molding.

The Plastic Molding Processes:

Injection Molding

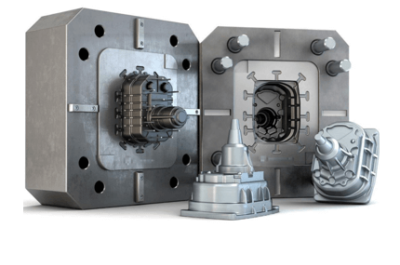

In the process of Injection Molding, melted plastic is forced into a

mold cavity. The mold can be removed once it is cooled. In mass-production or

prototyping of a product, this plastic molding process is commonly used. In the

1930s injection molding machines were made. To mass-produce bottle caps, toys,

kitchen utensils, and cell phone stand to name a few these can be used.

Blow molding is quite similar to plastic injection mold making except

that hot liquid plastic pours out of a barrel vertically in a molten tube.

Examples of blow molding products are containers, bottles, and tubes.

Compared to injection molding equipment’s need in setting-up a blow molding business is relatively higher.

It is a very technical process. Experts in this manufacturing business

are needed for being competitive in the market. Therefore, before going into

this endeavor a very scientific and systematic study should be first made.